Light Rtm Manufacturing

But lrtm requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

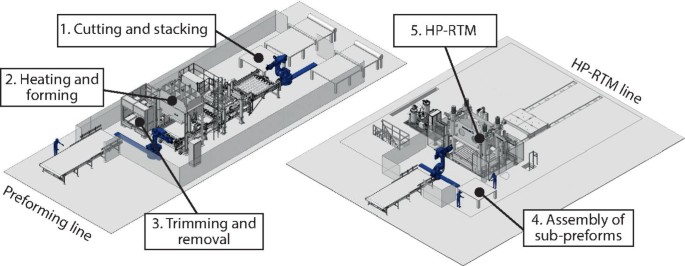

Light rtm manufacturing. Light rtm also produces finished surfaces on both sides of the part reduces labor costs enhances dimensional stability and improves process control. Like other closed molding composites processes light resin transfer molding lrtm offers reduced waste and emissions efficient materials use and a consistent and repeatable process. Light resin transfer molding or light rtm is a process by which composite products are manufactured using a closed mold system. Carbon fiber fiberglass kevlar thorstrand infusion specialty cloths epoxy polyester vinyl ester.

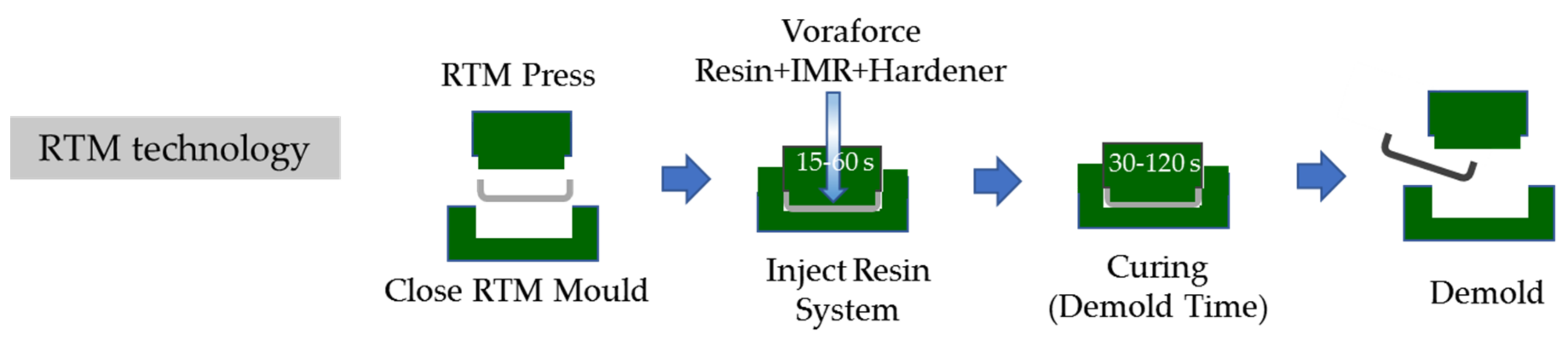

This method has rapidly become popular in recent years this method has rapidly become popular in recent years and it enables manufacturing of products with high strength and superior appearance by using simple molds. Light rtm is an excellent process for manufacturing parts that require both inside and outside finished surfaces. Light rtm lrtm is a vacuum assisted closed molding process capable of high quality two sided finishes molded at low to moderate production volumes. It consist of inserting resin between two tightly fitting moulds with small pressure.

Lrtm light resin transfer moulding is one of the technologies of creating compound products. This video shows a vacuum clamped rtm test panel mould in use. Fiberglass reinforcement is put dry in the mould which is covered with gel coat. The closed mold consists of an a side mold base mold and a semi rigid b side mold counter mold that is sealed to the a side mold using vacuum pressure.

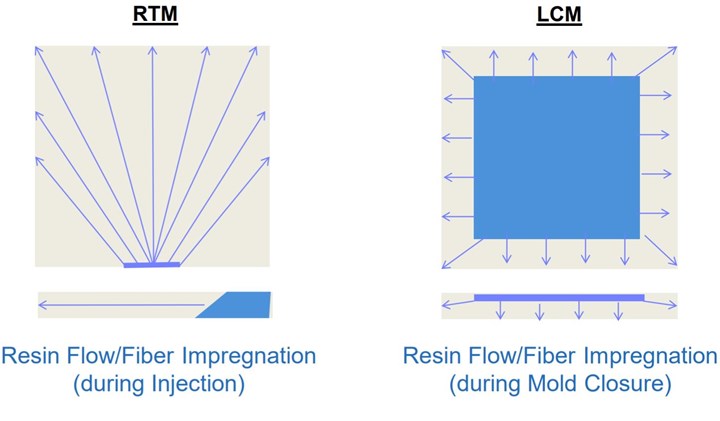

This type of mould has been supplied by composite integration ltd to r d facilities universit. Rtm light is one of the many liquid composite moulding lcm closed mould composites manufacturing processes. Additionally the whole process is supported by vacuum pressure.