Large Deformation Analysis Of A Rubber Sheet With Holes

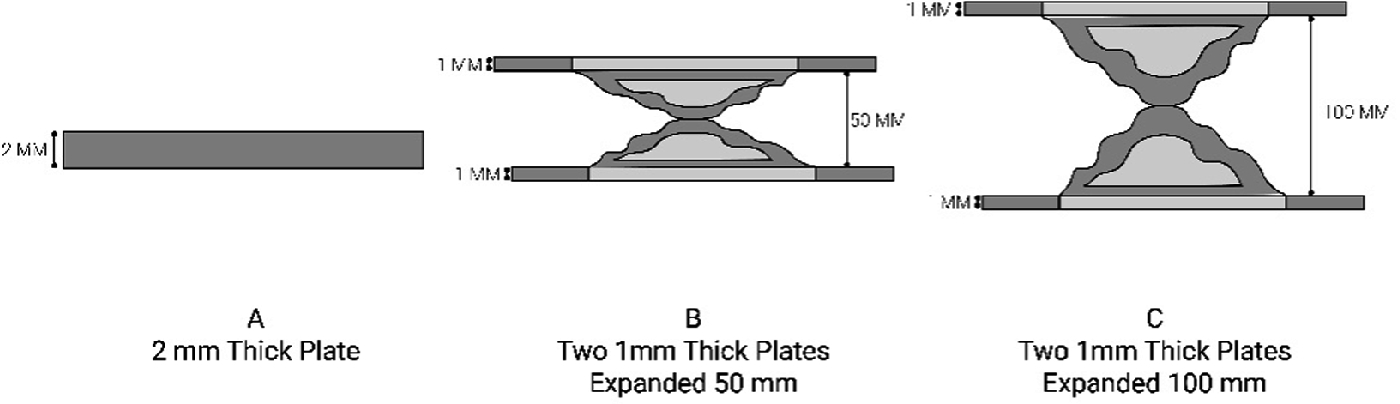

The large displacement solution is required when the acquired deformation alters the stiffness the ability of the structure to resist loads significantly.

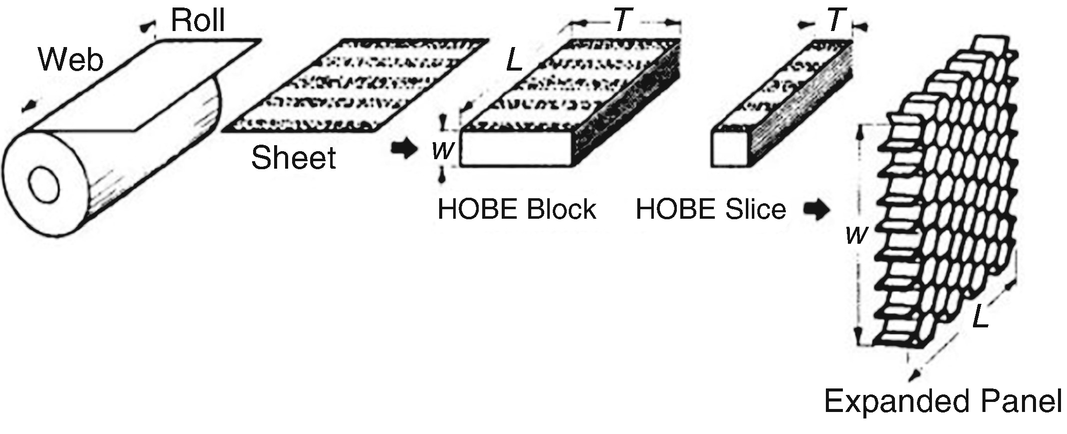

Large deformation analysis of a rubber sheet with holes. Its fidelity for predicting large deformation is established by comparison with those of finite element analysis of a rubber sheet with a hole under stretch. As shown in fig. The vertical stiffness and deformation theories of rubber isolators in compression and compression shear states are systemically researched in the paper a series of basic concepts such as origin. Hence a square is topologically equivalent to a circle.

10 the rubber sheets have two edge notches of length of a 12 16 20 24 28 mm and the notch radius is 1 mm the boundary conditions are the same as those of previous configuration with a hole. In this study a yield criterion is discussed for the perforated sheet with uniform circular holes by employing an equivalent continuum approach which is then applied to examine the plastic deformation of the perforated sheet with non uniform circular holes. For example a square can be deformed into a circle without breaking it but a figure 8 cannot. Rubber sheets with double edge notches.

Quire the characterisation of the deformation behaviour of a perforated sheet containing a large number of holes. But on a rubber sheet that is deformed by a small amount this relation turns out to be reversed t 3 is proportional to r 2. Patenadue et al 2005 evaluated the response of elastomeric blocks under large compression strains and quantitatively measured the nonlinear behavior of rubber compounds under. It is sometimes called rubber sheet geometry because the objects can be stretched and contracted like rubber but cannot be broken.

The tensile displacement is applied on the top boundary in the vertical direction in increments of 0. 25 mm until the onset of damage. You can use a large displacement solution. Topology studies properties of spaces that are invariant under any continuous deformation.

The analysis of the stress and strain in the perforated material is based on treating the perforated material as an equivalent solid material 1 2. Deformation analysis of silicone rubber sheet subjected to keen wc blade indentation article in international journal of automation technology 8 5 761 772 september 2014 with 32 reads. And this changes as the deformation becomes larger.